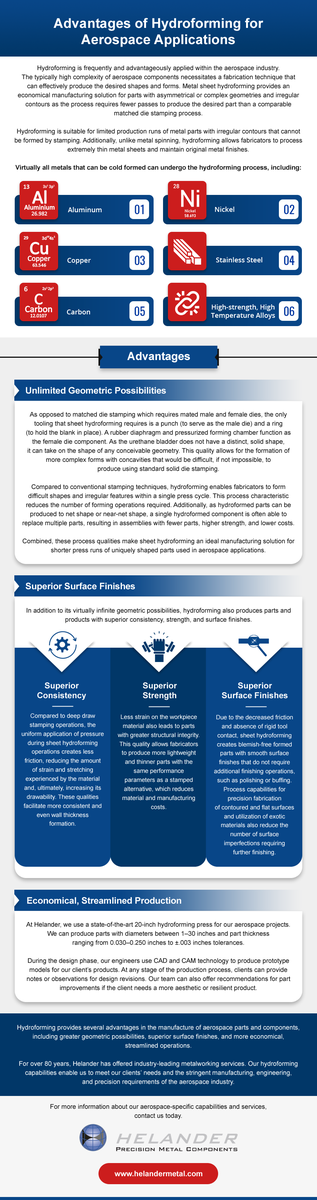

Hydroforming is frequently and advantageously applied within the aerospace industry. The typically high complexity of aerospace components necessitates a fabrication technique that can effectively produce the desired shapes and forms. Metal sheet hydroforming provides an economical manufacturing solution for parts with asymmetrical or complex geometries and irregular contours as the process requires fewer passes to produce the desired part than a comparable matched die stamping process.

effectively produce the desired shapes and forms. Metal sheet hydroforming provides an economical manufacturing solution for parts with asymmetrical or complex geometries and irregular contours as the process requires fewer passes to produce the desired part than a comparable matched die stamping process.

Hydroforming is suitable for limited production runs of metal parts with irregular contours that cannot be formed by stamping. Additionally, unlike metal spinning, hydroforming allows fabricators to process extremely thin metal sheets and maintain original metal finishes.

Virtually all metals that can be cold formed can undergo the hydroforming process, including:

- Aluminum

- Nickel

- Copper

- Stainless steel

- Carbon

- High-strength, high-temperature alloys

In addition to the wide range of suitable materials, hydroforming offers a number of unique advantages for the aerospace industry. The following blog post will provide an overview of these advantages.

Unlimited Geometric Possibilities

As opposed to matched die stamping which requires mated male and female dies, the only tooling that sheet hydroforming requires is a punch (to serve as the male die) and a ring (to hold the blank in place). A rubber diaphragm and pressurized forming chamber function as the female die component. As the urethane bladder does not have a distinct, solid shape, it can take on the shape of any conceivable geometry. This quality allows for the formation of more complex forms with concavities that would be difficult, if not impossible, to produce using standard solid die stamping.

Compared to conventional stamping techniques, hydroforming enables fabricators to form difficult shapes and irregular features within a single press cycle. This process characteristic reduces the number of forming operations required. Additionally, as hydroformed parts can be produced to net shape or near-net shape, a single hydroformed component is often able to replace multiple parts, resulting in assemblies with fewer parts, higher strength, and lower costs.

Combined, these process qualities make sheet hydroforming an ideal manufacturing solution for shorter press runs of uniquely shaped parts used in aerospace applications.

Superior Surface Finishes

In addition to its virtually infinite geometric possibilities, hydroforming also produces parts and products with superior consistency, strength, and surface finishes.

- Superior consistency. Compared to deep draw stamping operations, the uniform application of pressure during sheet hydroforming operations creates less friction, reducing the amount of strain and stretching experienced by the material and, ultimately, increasing its drawability. These qualities facilitate more consistent and even wall thickness formation.

- Superior strength. Less strain on the workpiece material also leads to parts with greater structural integrity. This quality allows fabricators to produce more lightweight and thinner parts with the same performance parameters as a stamped alternative, which reduces material and manufacturing costs.

- Superior surface finishes. Due to the decreased friction and absence of rigid tool contact, sheet hydroforming creates blemish-free formed parts with smooth surface finishes that do not require additional finishing operations, such as polishing or buffing. Process capabilities for precision fabrication ofcontoured and flat surfaces and utilization of exotic materials also reduce the number of surface imperfections requiring further finishing. By minimizing the amount of finishing operations required, the hydroforming process decreases the total cost of production.

The above advantages lead to hydroforming being the manufacturing technique of choice for critical aerospace parts and components that require superior surface finishes.

Economical, Streamlined Prototyping

Hydroforming provides a quick, low-cost prototyping solution. Compared to the tooling used in similar manufacturing processes, hydroforming tooling can be up to 90% less expensive.

At Helander, we use a state-of-the-art 20-inch hydroforming press for our aerospace prototyping projects. We can produce parts with diameters between 1–30 inches and part thickness ranging from 0.030–0.250 inches to ±.003 inches tolerances.

During the design phase, our engineers use CAD and CAM technology to produce prototype models for our client’s products. At any stage of the production process, clients can provide notes or observations for design revisions. Our team can also offer recommendations for part improvements if the client needs a more aesthetic or resilient product.

Our hydroforming capabilities, combined with our commitment to maintaining open client communication, results in superior quality metal components for precise aerospace application needs. For more information about our aerospace-specific capabilities and services, contact us today.

Contact Helander Today

Hydroforming provides several advantages in the manufacture of aerospace parts and components, including greater geometric possibilities, superior surface finishes, and more economical, streamlined operations.

For over 80 years, Helander has offered industry-leading metalworking services. Our hydroforming capabilities enable us to meet our clients’ needs and the stringent manufacturing, engineering, and precision requirements of the aerospace industry. To learn more about our hydroforming services and capabilities for aerospace applications, contact us today.