Pleased to serve the alternative energy and green industries, Helander manufactures alternative and green energy components using our superior hydroforming, spinning, welding, and machining processes. As an emerging and evolving industry, we supply fabricated components to improve performance and efficiency of alternative energy systems.

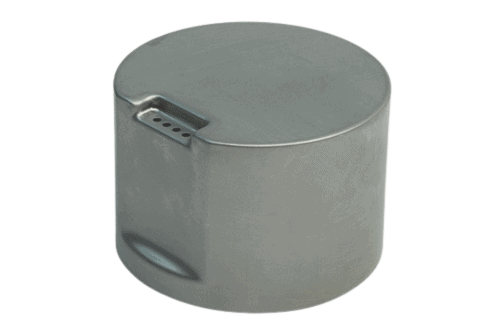

With the ability to hold tolerances down to +/-0.003”, we offer unparalleled precision and quality and can meet exacting requirements: we offer material thicknesses from 0.018” to 0.250” , a 72” maximum product length, and an up to 80” maximum product diameter. We work with several types of materials, including 316 and 321 stainless steel, and 7075, 5052, and 6061 aluminum.

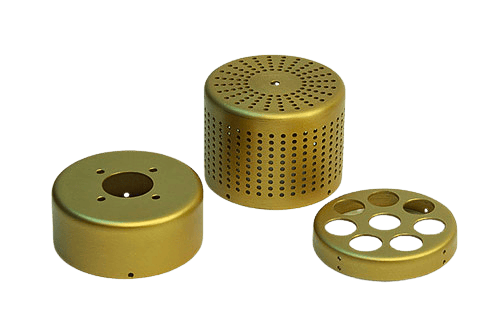

If required, we can finish components with a gold anodization process. Our components are appropriate for use within solar energy, steam energy, wind energy, and fuel cell applications, and we can accommodate orders from 1 to 50,000 pieces. And with international delivery service, we can complete your order in just 4 to 12 weeks.

Helander has the capabilities to deliver high-quality components that conform to rigid specifications. Our outstanding products feature structural integrity to meet the demanding challenges found in the energy sector. To learn more about our alternative and green energy components and how we can help you, please contact us today.

Specifications for the Green & Alternative Energy Industry

| Capabilities Applied/Processes | Hydroforming, Spinning, Welding, Machining |

| Tightest Tolerance | (+/-0.003") |

| Material Thickness | 0.018" to 0.250" |

| Product Length | Up to 72" |

| Product Diameter | Up to 80" |

| Cutting Method | CNC Turning & Milling |

| Typical Materials Used | 316s/s, 321 s/s, 7075Al, 5052 Al, 6061 Al |

| Industry for Use | Solar Energy, Steam Energy, Wind Energy, Fuel Cells |

| Volume | 1pcs to 50,00pcs |

| Typical Delivery Time | 4 to 12 weeks |

| Delivery Location | International |

| Typical Tooling Cost |