Difficulties in Metal Spinning Special Alloys

Leave a CommentToo often in the metal fabrication industry, the phrase “we’re not set up for that” really means “we don’t want to do that.” When customers are met with either the unwillingness to manufacture their parts to print or the inexperience to know how to do so properly, the end project suffers greatly. Granted, it’s important for designs to be practical and feasible, but when a manufacturer says, “metal spinning with special alloys is just too difficult” it’s simply not true…for Helander anyway.

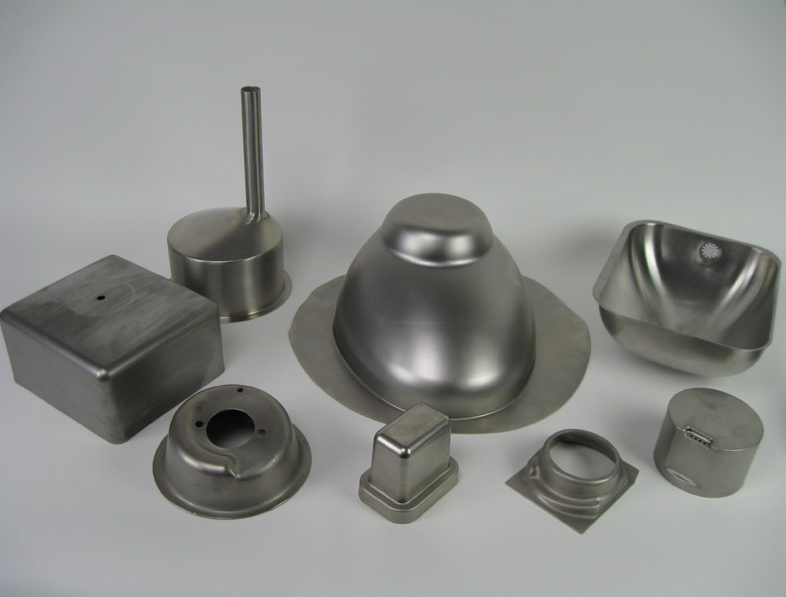

Special alloys are in no way a hindrance to getting the custom parts you want, in the specifications you want them, and in the tightest of tolerances. In fact, one of the major advantages of creating parts via metal spinning is the ability to create quality, uniform, products out of traditional metal, alloys, and exotics alike. As long as a part is ductile it can be metal spun and even high-strength alloys are workable and machinable.