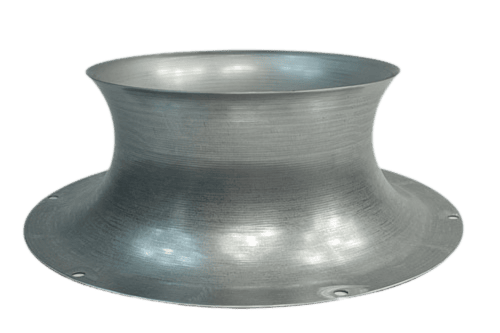

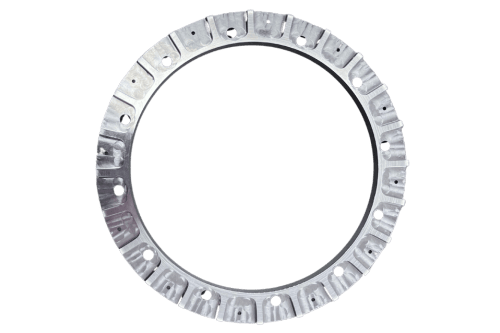

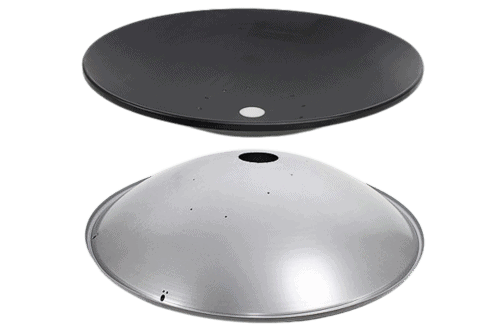

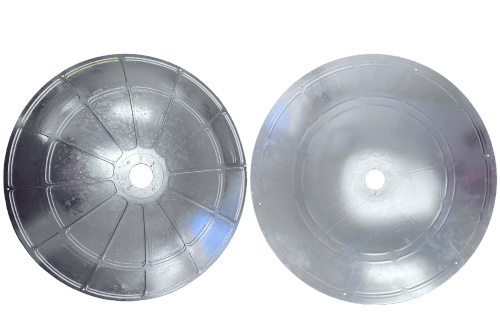

Helander Metal Spinning Company specializes in custom metal spun components tailored to customer specifications.

Advantages of Metal Spinning

Metal spinning offers advantages for a consistent, streamlined process, including:

Design Flexibility:

Metal spinning can change quickly to accommodate evolving product designs, allowing for maximal flexibility whenever a need arises.

Seamless, High-Quality:

Metal spinning produces smooth, durable parts without seams or welds for components that require superior strength and aesthetic.

Lower-Cost Tooling:

Compared to the tooling in alternative forming methods, like stamping, casting, & forging, metal spinning tools are typically 10% of the cost.

Shorter-Lead Times:

The metal spinning process allows for significantly shorter turnaround-times. Tooling and spun components can be available within weeks.

In addition to metal spinning, Helander offers in-house tooling, hydroforming, and machining. Our value-add services include abrasive polishing and Nadcap Accredited Welding to reduce cost, streamline production, and be your single-source for completed, plug & play components, ready for assembly.

To find out if metal spinning would be beneficial for your application, contact us today.