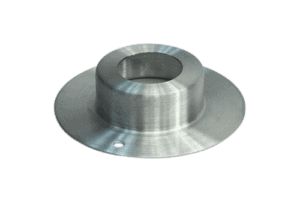

Helander offers custom pump components that meet the precise specifications required of industrial pumping applications. With the highest quality metal fabrication capabilities in the industry today, Helander is the top choice among aerospace, automotive, medical, and defense companies requiring the highest quality engineered and manufactured components.

Industrial pump components are manufactured using hydroforming, metal spinning, and welding processes. We produce components from metals such as stainless steel or aluminum with thicknesses that range from 0.022” to 0.135”. Our capabilities allow us to fabricate parts in a wide range of sizes to meet virtually any application. Available surface finishes range from 2B to #4 brush finish and meet requirements for corrosion resistance. Precisely engineered components are fabricated to exact specifications with typical tolerances held to ±0.010”.

To learn more about our industrial pump components and additional capabilities and services, please contact Helander.

Specifications for Industrial Pump Components

| Capabilities Applied/Processes | Hydroforming, Metal Spinning, Welding |

| Typical Tolerance | (+/-0.010") |

| Typical Material Thickness | from 0.022" to 0.135" |

| Material Finish | from 2B finish to #4 brush finish |

| Industry for Use | Industrial Pumps |

| Typical Annual Volume | 100pcs to 5000pcs |

| Typical Delivery Time | 4-12 weeks |

| Delivery Location | International |

| Typical Tooling Cost | $1500.00 to $3500.00 |