There are many reasons why metal polishing services are needed for precision metal components. The gleaming finish provides a high-end look to resulting metal components, including those made for home appliances, automobiles, and decorative objects, and many other consumer and industrial applications. The metal polishing process uses abrasion polishing compounds to remove surface imperfections and create a uniform grain preparing the part surface for inspection and surface finishing such as anodize, paint, plating and buffing.

Industries that utilize metal polishing services include, but are not limited to:

- Aerospace and defense

- Architectural

- Commercial and residential cookware or kitchenware

- Automotive

- Marine

- Lighting

For a more foundational overview of the metal polishing process itself, as well as equipment involved and application details, check out our Basics of Metal Polishing webpage.

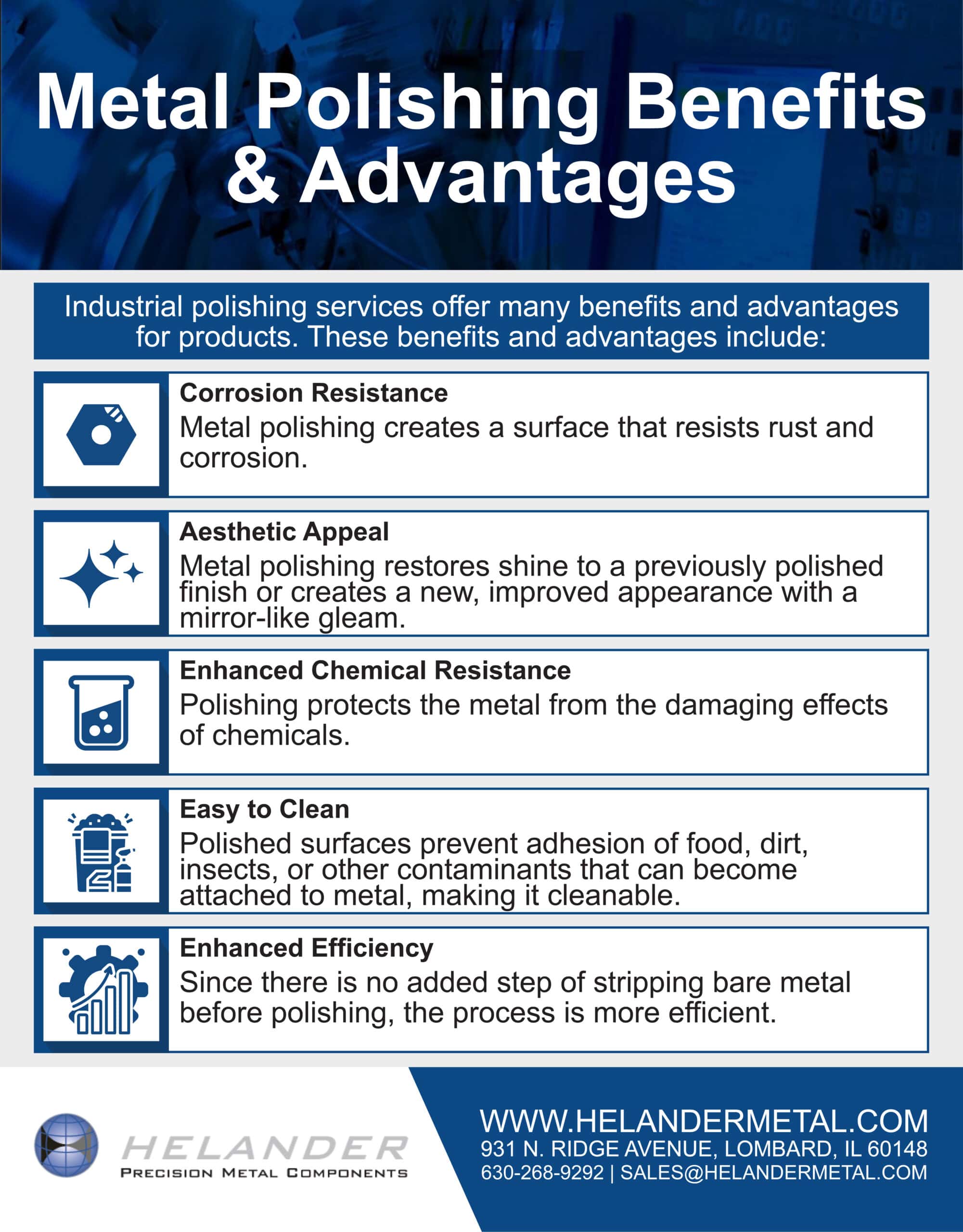

Metal Polishing Benefits & Advantages

Industrial polishing services offer many benefits and advantages for products, such as:

- Corrosion resistance. Metal polishing creates a surface that resists rust and corrosion.

- Aesthetic appeal. Metal polishing restores shine to a previously polished finish or creates a new, improved appearance with a mirror-like gleam.

- Enhanced chemical resistance. Polishing protects the metal from the damaging effects of chemicals.

- Easy to clean. A polished surface prevents adhesion of food, dirt, insects, or other contaminants that can become attached to metal, making it very easy to clean.

- Enhanced efficiency. Since there is no added step of stripping bare metal before polishing, the process is more efficient.

Metal Polishing Capabilities

Helander Metal’s metal polishing services accommodate many types of metals and alloys, including:

Value-Add Services: Metal Polishing

Metal polishing offers many aesthetic and functional benefits that are required in many applications.

For over 80 years, Helander has partnered and provided some of the most recognizable companies in the US with metal polishing services – including industries such as aerospace and defense, architecture, commercial food, medical, and more.

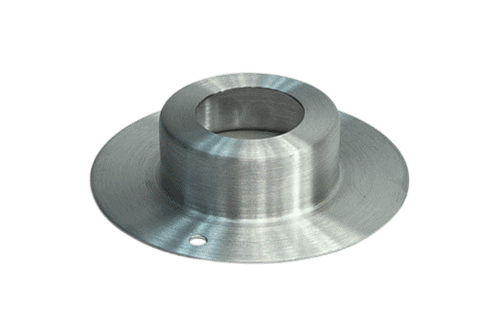

Our advanced manual lathe and turntable metal polishing equipment can provide parts with rough to fine polishing up to a #4 brush finish. Our advanced metal polishing services have assisted the needs of several industries.

Meeting high industry standards, we offer metal polishing finishes ranging from 36 to up to 240 grit. With the ability to apply our services to all metals including stainless steel, steel, copper, brass, bronze, aluminum. Our metal polishing operations can be used for a broad range of applications, including assemblies, decorative items, recreational products, and threads.

We invite you to contact us today to learn more about our superior metal polishing capabilities and the metal polishing process or to inquire after any of our additional partnered service options, which include plating, anodizing, electro-polishing, and painting.

Our highly-trained and experienced team can provide polishing services for many common and exotic metals. We are proud to provide partner services from metal polishing to plating, anodizing, electro-polishing, and painting.

For more information on our capabilities, contact us or request a quote today.