Stainless steel components used in the waste storage industry must meet the highest standards and requirements. Components must be able to withstand high temperatures and pressures.

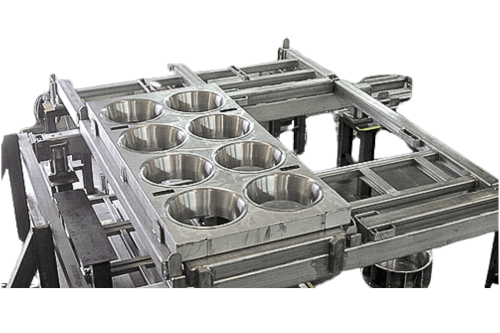

Utilizing the metal spinning process to fabricate components allows us to make intricate shapes while maintaining tensile strength, hardness, and resistance to fatigue.

Using a combination of our refined spinning and welding processes, Helander works with 304, 316, and 321 stainless steel to fabricate components for the waste storage industry.

Holding tight tolerances, down to ±0.020”, we pride ourselves on providing our clients with the utmost precision and quality. With material thicknesses up to 0.250” in stainless steel, and an 72” maximum product diameter. Additionally, we can achieve a surface finish up to 63 Ra, and depend on CNC machining as our primary cutting method.

And with delivery times from 4 to 12 weeks, we make sure you receive your order when you need it. We’re pleased to accommodate orders up to 5,000 pieces.

To learn more about our spinning and welding processes for the waste storage industry, please contact Helander today.