Helander manufactures custom kitchen equipment and components for commercial food applications using stainless steel and other popular metals. Our range of machining capabilities, including metal spinning, hydroforming, welding, and custom tube making, enable us to manufacture any component to exacting specifications. As a leader in all types of metal forming, we easily meet the needs of our customer’s most challenging projects, from prototyping to large-scale production.

Our precision capabilities have led us to produce a wide range of products used in the food industry. Understanding the specific requirements for food safety helps us support our customers in each step of the manufacturing process. Whether the component is a cooking kettle, a decorative item, or an even larger piece of equipment, our products and manufacturing processes meet the highest food-grade quality standards.

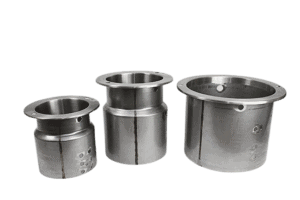

Stainless Steel Equipment Fabrication

When producing custom kitchen equipment, the most popular metal used is 300 series stainless steel; though, we do manufacture components from aluminum, brass, copper, and steel, as well. In the commercial food industry, parts and equipment are typically produced using 304 and 316 stainless steel due to their ability to prevent rust and stains from harming the work surface. These metals won’t react with alkaline foods or acids either.

Another reason you might consider these steel varieties for your projects are their resistance to dings, dents, and scratches. That means your equipment won’t suffer at the hands of everyday wear-and-tear, and the typical abuse sustained in commercial kitchen environments. Maintaining stainless steel is an easy feat and can be achieved by scrubbing down the surfaces with soap and water, or running through a dishwasher.

Equipment Specifications

Helander manufactures food equipment with materials ranging in thickness from 26 gauge to ¼ of an inch, with product lengths between 1” and 20” (3″ to 36″) and outside diameter widths between 4” and 20” (1″ to 72″ OD). We typically hold tolerances down to ±0.015”. Surface finishes are smooth or brushed and provide corrosion resistance, suitable for high temperature and wet environments. Optional finishes include baked enamel or paint to increase aesthetic value.

To learn more about our commercial food equipment fabrication and other services, please contact Helander.

Specifications for Stainless Steel Commercial Food Equipment

| Capabilities Applied/Processes | Metal Spinning, Welding, Custom Cylinder |

| Standard Tolerances | (+/-0.015") to (+/-.045”) |

| Material Thickness | 26 gauge to ¼" |

| Typical Product Length | 3" to 36" |

| Typical Product Width | 1" to 72" OD |

| Surface Roughness | 2B to 32Ra / #4 brush finish |

| Cutting Method | CNC Turning and Milling |

| Common Material Used | 300 series stainless steel |

| Industry for Use | Commercial Food Equipment |

| Typical Volume | 1 pcs to 50,000 annually |

| Typical Delivery Time | 4 to 12 weeks |

| Delivery Location | International |

| Typical Tooling Cost | $1500.00 to $5000.00 |