Prototyping

To ensure a successful end design and minimal downtime, our team offers sophisticated hydroforming and spinning prototyping services. A very cost-efficient process, hydroforming prototyping is ideal for creating metal parts with highly irregular or complex shapes and sizes. Using CAD and CAM technology, our engineers work closely with clients throughout the entire design process, making adjustments as necessary.

Allowing for operation in either deep draw mode or fluid cell process mode, our cutting-edge 20-inch hydroforming press can operate up to 10,000 psi, with a max punch tool diameter of 15 inches and a draw depth capacity of 12 inches. Deep draw mode is ideal for parts with curved geometries, while fluid cell process mode allows for the production of several parts during a single run.

Spinning prototyping can be accomplished by using various techniques such as automated, manual or shear forming. Technique selected depends on part geometry, material type, thickness and order quantity. Formed parts then go thru secondary operations such as heat treatment, resizing, machining, polishing, etc. as dictated by drawing requirements.

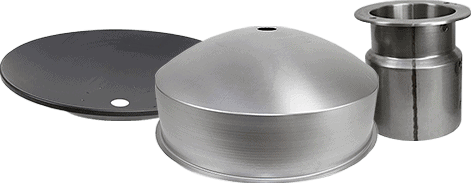

Custom Spun Metal Services

Supported by in-house tooling services and a skilled prototyping team, metal spinning at Helander can take a project straight from design to completion. The cold forming metal spinning process is particularly well-suited to making hollow parts, especially those requiring a circular cross section or conical shape.

Our technicians utilize advanced CNC, power-assisted, and manual forming processes to craft high-performance custom spun metal fabricated components with up to 36 inches between centers.

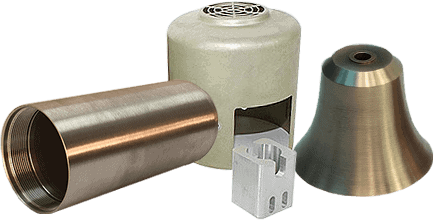

Metal Hydroforming

A modern alternative to conventional stamping, welding, and prototyping methods, metal hydroforming offers quick, efficient, and reasonably priced results with minimal waste. This process applies pressurized hydraulic fluids to ductile metals to shape intricate components with excellent structural strength and minimal secondary finishing.

Hydroforming is a popular choice for carbon steel, copper, aluminum, brass, and stainless steel parts used in defense, automotive, food service, and medical applications, among many others.

CNC Turning and Milling

The Helander facility is outfitted with two CNC mills and six CNC lathes to support our metal fabrication services; we use CNC for machining and tooling/fixturing. We routinely work with copper, brass, stainless steel, carbon steel, aluminum, and titanium, as well as other custom metals for various markets, like commercial food equipment, and aerospace applications.

Our team also offers a host of secondary services, including turning, drilling, milling, boring, threading, and tapping.

Metal Polishing

Offering rough to fine polishing with up to a #4 brush finish, our metal polishing services can create the perfect surface for your components. The Helander team regularly develops specialized finishes for assemblies, decorations, recreational products, threads, and more.

We also partner with trusted companies to offer plating, anodizing, electropolishing, and painting services to meet projects’ particular needs.

Custom Welding

Offering six different welding processes, Helander is a premier welding service provider. Our team specializes in GMAW (MIG), GTAW (TIG), soldering, and automated seam welding, along with cylindrical welding for tubing and pressure applications, as well as aerospace metal fabrication welding.

We proudly comply with NADCAP (National Aerospace and Defense Contractors Accreditation Program) regulations, as well as AWS (American Welding Society) and ASME (American Society of Mechanical Engineers) standards.

Custom Metal Fabrication Services From Helander

Helander works to develop top-quality, long-lasting custom components for industries of all kinds; commercial food and beverage, furnishings and construction, waste services, automotive design, HVAC, medical, defense, aerospace, and communications are just a few of our specialties.

To learn more about any of the metal fab services listed here, or to discuss your next project with an expert, reach out to the team today.