Helander Metal Spinning Company specializes in custom metal spun components tailored to customer specifications.

What is Metal Spinning?

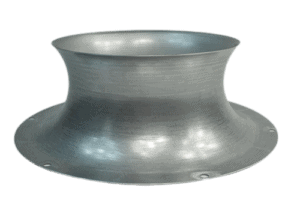

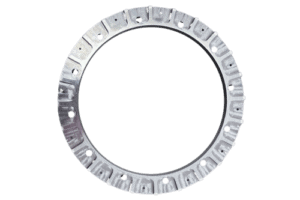

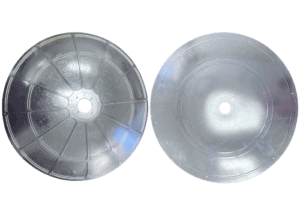

Metal spinning – also called spin forming– is a metalworking process by which high-performance, axially symmetric parts are created. Unlike other metal forming processes that cut and remove material to produce a desired shape, metal spinning transforms a metal disc or tube —known as the blank— by rotating it on a lathe and applying pressure to form it to a mandrel, and produce a conical, toroidal, or other round shape.

Metal spinning can be done in automatic CNC machines, hydraulic-assist machines, or by manually hand spinning. Spinning equipment is chosen based on production volume and intricacy of the part. This process can be performed hot or cold, depending on material.

Helander Metal Spinning Company has the capability to spin parts as large as 60” in height and 100” in diameter, in a variety of material thicknesses. The ability to form high-quality, thick components, and large diameters with uniformity at any quantity makes metal spinning an appealing and versatile production method.

Advantages of Metal Spinning

Metal spinning offers advantages for a consistent, streamlined process, including:

Design Flexibility: Metal spinning can change quickly to accommodate evolving product designs, allowing for maximal flexibility whenever a need arises.

Seamless, High-Quality: Metal spinning produces smooth, durable parts without seams or welds for components that require superior strength and aesthetic.

Lower-Cost Tooling: Compared to the tooling in alternative forming methods, like stamping, casting, & forging, metal spinning tools are typically 10% of the cost.

Shorter-Lead Times: The metal spinning process allows for significantly shorter turnaround-times. Tooling and spun components can be available within weeks.

In addition to metal spinning, Helander offers in-house tooling, hydroforming, and machining. Our value-add services include abrasive polishing and Nadcap Accredited Welding to reduce cost, streamline production, and be your single-source for completed, plug & play components, ready for assembly.

| Metal Spinning Capabilities | ||

| Automatic CNC Spinning | ||

| Hydraulic-Assist Spinning | ||

| Manual Hand Spinning | ||

| Typical Tolerance | Max Height | Max Diameter |

| +/- 0.030” | 60” | 100” |

| Materials | Thickness | |

| Hastelloy | Stainless Steel | 0.018” to 1.25” |

| Monel | Carbon Steel | 0.018” to 1.50” |

| Inconel | Aluminum | 0.018” to 2.00” |

| Bronze | Copper | 0.018” to 2.00” |

| Brass | Titanium | |

| Typical Volume | Lead Time | Delivery |

| 1 to 50K Units | 2 to 12 Weeks | Worldwide |

Metal Spinning Applications

Metal spinning presents a cost-effective production method for a wide range of commercial and industrial applications, including:

- Combustor: Dome Deflectors, Liners, Shields

- Exhaust: Heat Shields, Nozzles

- Externals: Manifolds

- Turbine: Bearing Housings

- Rockets: Combustion Chamber Liner; Inconel Housings

- Defense: Artillery Components

Commercial

- Automotive: Seal Rings, Wheel Rims, Hubcaps

- Food Processing: Kettles, Fryers, Grill Housings, Heat Lamps, Appliance Components, Cooktops, Lids, Hoppers, Funnels

- Fixtures & Furniture: Table & Chair Bases, Light Fixtures

- Medical: MRI Scanner Vessel Ends, Shields

- Oil & Gas: Combustor Liners, Valves, Bearing Housing

- Nuclear: Waste Disposal Containers; Nuclear Fuel Handling and Storage Assemblies

- Renewable: Bearing Cages, Pylons

- Equipment & System Components: Pump Caps, Rings, Ladles, Venturi, Inlets, Wheels, Cones, Rings, Sleeves, Electrical Gauge Components, Air Flow Nozzles, Pressure Vessel Tanks

- Satellite Communications: Satellite Dishes, Antenna Reflectors, RF Housings

To find out if metal spinning would be beneficial for your application, contact us today.