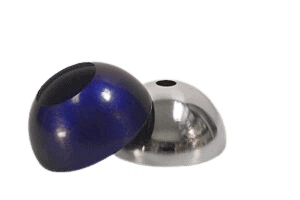

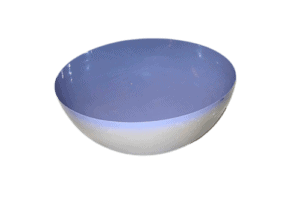

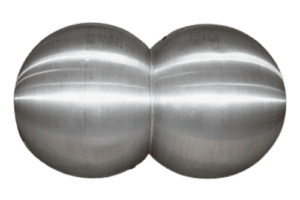

Metal Hemispheres

We manufacture featured metal hemispheres for aerospace, geological, and other diverse applications. Working with aluminum, copper, brass, steel, and other materials, we apply a combination of CNC metal spinning, hot spinning, machining, welding, and polishing to fabricate our spheres.

We can achieve up to a #4 brush finish, and hold tight tolerances down to 0.005 of an inch. Final material thicknesses range from 0.018 of an inch to ¾ of an inch, with a maximum 60″ outside diameter width and a maximum 30″ product height.

Helander can accommodate orders between 1 and 50,000 pieces. To learn more about our metal hemispheres, please contact us.

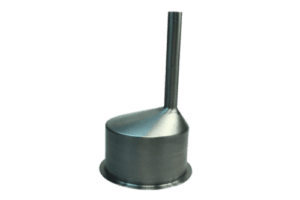

Metal Cone and “Bullet” Shapes

Appropriate for a range of industries, such as concrete testing, alternative energy, and soil testing, these featured metal cone and bullet shapes are manufactured using a combination of CNC metal spinning, hydroforming, and double roller shear forming.

We can fabricate these metal shapes from aluminum, copper, brass, stainless steel, or carbon steel, and we offer either zinc plating or #4 polish material finish.

We feature a material thickness between 0.030″ and 0.250″, and can achieve a maximum product outside diameter of 48″ and a product height up to 36″. Our superior methods enable us to hold tolerances down to +/- 0.010″. To learn more about out metal cone and bullet shapes, please contact us today.

Specifications for Metal Hemispheres & Metal Cones

| Capabilities Applied/Processes | CNC Spinning, Hot Spinning, Machining, Polishing, Welding |

| Typical Tolerance | (+/-.015") |

| Material Thickness | 0.018" to 0.750" |

| Typical Product Width | 60" diameter |

| Typical Product Height | 30" height |

| Cutting Method | CNC Turning |

| Material Used | Aluminum, Copper, Brass, Steel, Stainless, Titanium, Hastalloy, Inconnel, Monel |

| Material Finish | #4 brush finish |

| Industry for Use | Aerospace, Geological, Laboratory, Gage Instrumentation, Food |

| Typical Delivery Time | 4 to 12 weeks |

| Delivery Location |