Helander Metal Spinning Company specializes in forming custom metal components tailored to customer specifications. One of our core capabilities is Hydroforming.

What is Hydroforming?

Sheet hydroforming is a metal fabrication technique that leverages pressurized fluid to form and shape ductile metal into desired components using pre-shaped plates or dies. As part of this process, a flat metal disc —known as the blank— is placed onto a mechanically driven mandrel. The hydraulic fluid is pumped into the chamber behind a rubber diaphragm that is the counter pressure to the rising mandrel. This causes the metal to draw until it takes the shape of the mandrel.

Hydroforming is a quick, efficient, and affordable metal forming method that reduces wastage while guaranteeing structurally robust parts and components with minimal need for secondary finishing operations.

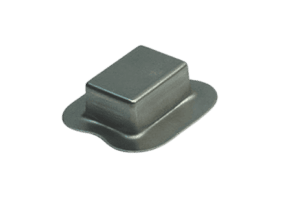

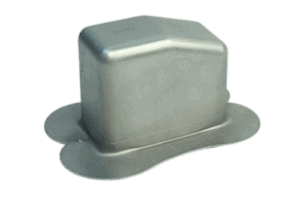

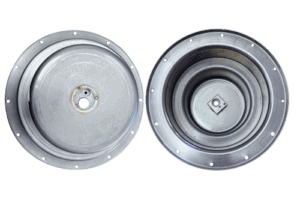

Hydroforming is ideal for shaping intricate, exceptionally complex, or asymmetrical components.Both convex and concave shapes can be attained using this metal forming method.

Helander Metal Spinning Company has the capability to hydroform parts up to 12” deep and 19” in diameter, in a variety of material thicknesses. The ability to form high-quality, uniform, seamless components at any quantity with minimal secondary finishing makes hydroforming an appealing and versatile production method.

Advantages of Hydroforming

Hydroforming is a smart alternative to conventional methods, such as stamping, for a variety of reasons, including:

Fast & Efficient: Hydroforming takes about 20 seconds to form seamless, structurally sound parts within +/- 0.003” tolerance and reduces the need for secondary finishing operations.

Complex shapes: Hydroforming is ideal for creating complex, unusually-shaped parts.

Cost-Effective: Hydroforming is suitable and cost-effective for short, medium, and large production runs. Hydroforming is ideal for prototyping due to the high versatility in regard to design changes.

Sustainable: Hydroforming produces little to no scrap, especially when compared to metal stamping.

In addition to hydroforming, Helander offers in-house tooling, metal spinning, and machining. Our value-add services include abrasive polishing and Nadcap Accredited Welding to reduce cost, streamline production, and be your single-source for completed, plug & play components, ready for assembly.

| Hydroforming Capabilities | ||

| 15″ Press; 7″ Draw Depth – 12″ Diameter – 15″ Blank | ||

| 20″ Press; 10″ Draw Depth – 15″ Diameter – 20″ Blank | ||

| 25″ Press; 12″ Draw Depth – 19″ Diameter – 25″ Blank | ||

| Typical Tolerance | Max Depth | Max Diameter |

| +/- 0.003” | 12” | 19” |

| Materials | Thickness | |

| Hastelloy | Stainless Steel | 0.018” to 0.105” |

| Monel | Carbon Steel | 0.018” to 0.250” |

| Inconel | Aluminum | 0.018” to 0.250” |

| Bronze | Copper | 0.018” to 0.250” |

| Brass | Titanium | |

| Typical Volume | Lead Time | Delivery |

| 1 to 50K Units | 2 to 12 Weeks | Worldwide |

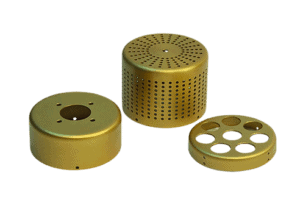

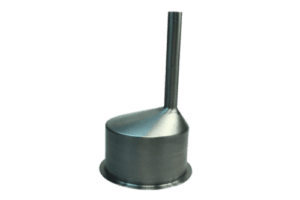

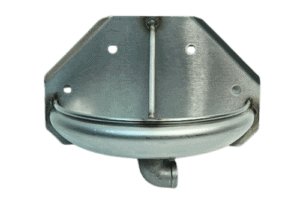

Hydroforming Applications

Hydroforming presents a cost-effective production method for a wide range of commercial and industrial applications, including:

- Combustor: Shields

- Exhaust: Heat Shields

- Externals: Manifolds, Engine Housing

- Turbine: Bearing Housings

- Cabin Components: Lavatory Sinks

Commercial

- Food Processing: Lids, Bowls, Funnels, Hoppers, Canisters

- Fixtures & Furniture: Light Reflectors & Fixtures

- Oil & Gas: Electrical Housing

- Nuclear: Waste Disposal Containers; Nuclear Fuel Handling and Storage Assemblies

- Renewable: Bearing Cages

- Equipment & System Components: Floats, Pump and Vacuum System Components & Housings, Water Valve & Pressure Gauge Components, Tank Heads

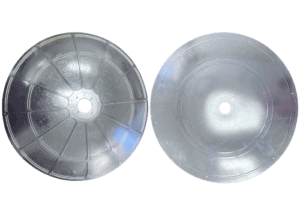

- Satellite Communications: Satellite Dishes, Antenna Reflectors, RF Housings

To find out if hydroforming would be beneficial for your application, contact us today.