Helander Metal Spinning Company specializes in precision CNC Machining of custom formed metal components for the Aerospace & Defense, Energy, and Commercial Industries.

What is CNC Machining?

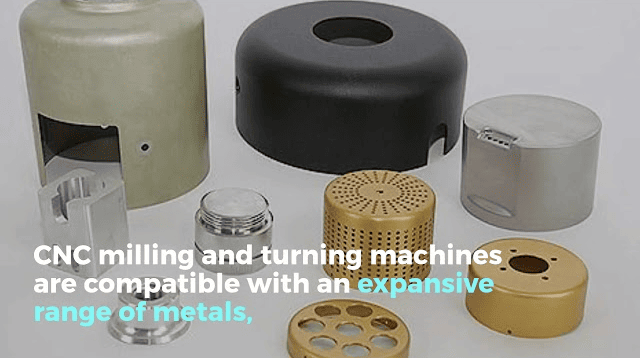

Computer Numerical Control (CNC) machining, is a manufacturing process that uses automated, high-speed cutting tools to remove layers of material from a stock piece —known as the blank or workpiece— to produce custom-designed parts. Standard CNC machines include 3-5-axis milling machines, lathes, and routers. Design Engineers provide CAD (computer-aided design) models to skilled CNC machinists and programmers that convert the model to CAM (computer-aided manufacturing) software, which dictates the movement of the CNC machine tool paths.

Machines vary in how CNC parts are cut—the workpiece may remain in place while the tool moves, the tool may remain in place while the workpiece is rotated and moved, or both the cutting tool and workpiece may move together.

Helander Metal Spinning Company’s vast in-house capabilities include a machine shop, equipped with 13 lathes and 7 mills that can cut almost any metal alloy, including high temp alloys such as Inconel and titanium, with high precision and repeatability, making custom machined parts suitable for nearly every industry. Helander’s continuous investment in advanced equipment and technology, paired with our in-house fixturing and tooling expertise, allow us to handle complex machining demands that meet your cost and production goals while maintaining the highest quality standards.

Helander’s CNC Machining Equipment List

Advantages of CNC Machining

Precision & Repeatability: The automated nature of CNC machining enables efficient, accurate and consistent production that would be impossible to achieve through a manual process.

Robust Secondary Service Capabilities: Machining can provide secondary finishing on previously formed components; trimming, threads, slots, or holes can all be added for further definition.

Cost-Effective: Machining is the most cost-effective manufacturing process for one-off and medium-volume production runs.

Tight tolerances: Both milling and turning produce very tight tolerance parts, which makes CNC ideal for high-end applications such as in aerospace & defense.

In addition to machining, Helander offers in-house tooling, metal spinning, and hydroforming. Our value-add services include abrasive polishing and Nadcap Accredited Welding to reduce cost, streamline production, and be your single-source for completed, plug & play components, ready for assembly.

| CNC Machining Capabilities | |

| 13 Lathes – Turning Centers | |

| 7 Mills – Machining Centers | |

| Typical Tolerance | +/- 0.001” |

| Materials | |

| Hastelloy | Stainless Steel |

| Monel | Carbon Steel |

| Inconel | Aluminum |

| Bronze | Copper |

| Brass | Titanium |

| Typical Volume | 1 to 50K Units |

| Lead Time | 2 to 12 Weeks |

| Delivery | Worldwide |

CNC Machining Applications

Machining presents a cost-effective production method for a wide range of applications, including:

- Combustor: Shields

- Exhaust: Heat Shields

- Externals: Manifolds, Engine Housing

- Turbine: Bearing Housings

- Defense: Artillery Components

Commercial

- Automotive: Seal Rings, Wheel Rims, Hubcaps

- Food Processing: Kettles, Fryers, Grill Housings, Heat Lamps, Appliance Components, Cooktops, Lids, Hoppers, Funnels

- Fixtures & Furniture: Table & Chair Bases, Light Fixtures

- Medical: MRI Scanner Vessel Ends, Shields

- Oil & Gas: Combustor Liners, Valves, Bearing Housing

- Nuclear: Waste Disposal Containers; Nuclear Fuel Handling and Storage Assemblies

- Renewable: Bearing Cages, Pylons

- Equipment & System Components: Pump Caps, Rings, Ladles, Venturi, Inlets, Wheels, Cones, Rings, Sleeves, Electrical Gauge Components, Air Flow Nozzles, Pressure Vessel Tanks

- Satellite Communications: Satellite Dishes, Antenna Reflectors, RF Housings

What is Turning?

The turning process uses a spindle to rotate a part, while tools move past it to remove material. There are various common tool and insert shapes for turning, grooving, and boring, as well as drills, taps, and reamers. Because the material is rotating in this process, the part is always symmetrical around the center of rotation.

A standard lathe has 2-axis control. The X axis is related to part diameter, and the Z axis moves along the length of the part. The back end of the part can be machined as well for a finished part in one operation. A common addition to turning machines is live tooling, which is often accompanied by another axis, called the Y axis. Machines with live tooling are capable of performing mill operations, such as drilling cross holes, or milling flats and slots. These machines are capable of making extremely complex parts without any secondary operations.

What is Milling?

The milling process uses rotating tools to remove material. While some tools such as drills, taps, and reamers can only plunge straight into the part, the most common cutter used on a mill is called an endmill. This tool not only cuts on the tip, but it can cut on the sides, allowing complex features to be machined.

A standard mill has 3-axis control. The X and Y axis move horizontally, and the Z axis moves vertically. Each axis can be controlled individually, such as for drilling or tapping where only the Z axis moves. They can also be moved simultaneously to make free-form contours. A common addition to a 3-axis mill is a 4th axis rotary indexer, which allows machining from more angles or machining the full perimeter of a cylindrical part.

Helander Metal Spinning Company’s CNC Machining Equipment List

Lathes – Turning Centers

| Make | Model | Axis | Chuck Size | Bar Capacity | RPM | HP | Max Cut Length | Max Cut Diameter |

| Haas | TL-2 | 2 | 8" | 2.3" | 1.8K | 10 | 48" | 16" |

| Haas | TL-3 | 2 | 12" | 3.0” | 1.8K | 18 | 60" | 20" |

| Haas | TL-3W | 2 | 12" | 3.5" | 1.8K | 30 | 60" | 30" |

| Haas | SL-30T | 2 | 10" | 3" | 3.4K | 30 | 32.5" | 15" |

| Haas | ST-30 | 2 | 10" | 3" | 3.4K | 30 | 32.5" | 15" |

| Haas | DS-30Y | 4 | 10" | 3" | 4.5K | 30 | 32.5" | 13.75" |

| Mori Seiki | ZL-45W | 4 | 24" | 3.6" | 2.5K | 60 | 40.6" | 30" |

| Mori Seiki | ZL-45B/1500 D | 4 | 24" | 3.6" | 2.5K | 60 | 40.6" | 30" |

| Mori Seiki | ZL-45MC/1500 E | 4 | 24" | 3.6" | 2.5K | 60 | 40.6" | 30" |

| Doosan | PUMA VT1100M | 2 | 40" | N/A | 850 | 75 | 39.4" | 43.3" |

| Doosan | PUMA 700 II | 2 | 32" | 6.5" | 3K | 60 | 126" | 35.4" |

Mills – Machining Centers

| Make | Model | Type | Axis | Size | RPM | HP | Max Cut Length | Max Cut Diameter |

| Haas | TM-3 | Vertical | 3 | Table Size 57.75" X 14.75" | 4K | 7.5 | Z-Axis 16" | X-Axis 40" Y-Axis 20" B-Axis 360° |

| Haas | VF-3SSYT | Vertical | 3 | Table Size 54" X 24" | 12K | 30 | Z-Axis 25" | X-Axis 40" Y-Axis 26" B-Axis 360° |

| Mori Seiki | SH50 | Horizontal | 4 | Pallet Size 19.6" | 12K | 30 | Z-Axis 25.6" | X-Axis 24.8" Y-Axis 23.6" B-Axis 360° |

| Mori Seiki | SH40 | Horizontal | 4 | Pallet Size 15.7" | 12K | 25 | Z-Axis 20" | X-Axis 22" Y-Axis 20" B-Axis 360° |

| Doosan | NHP 8000 | Horizontal | 4 | Pallet Size 31.5" | 10K | 50 | Z-Axis 53.9" | X-Axis 55.1" Y-Axis 47.2" B-Axis 360° |

To find out if machining would be beneficial for your application, contact us today.